Velo3D provides end-to-end metal 3D printing solutions for mission-critical parts in the space, transportation, and energy industries. Unlike conventional metal 3D printing solutions or traditional manufacturing methods, Velo3D helps design engineers build the complex parts they need without compromising their design or part quality.

https://www.youtube.com/channel/UCzAL6plbWPjh-IsPrVURI3A

The Velo3D end-to-end metal AM solution consists of:

- Flow™ print preparation software which is responsible for prescribing the manufacturing process for the Sapphire family of printers.

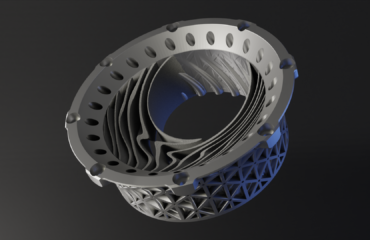

- The Sapphire® family of metal 3D printers are next-generation LPBF metal AM printers. With a re-engineered optics center, optimized gas flow, and a unique non-contact recoater, Sapphire® printers are capable of printing today’s most advanced geometries.

- Assure™ real-time quality validation and control software enables visibility into every layer of a part’s build.

- Intelligent Fusion is the underlying manufacturing process that binds and facilitates all aspects of the Velo3D end-to-end solution.

Referente AM

Roberto Esposito, Sales Director Italy

EMAIL: info_emea@velo3d.com

Visita la pagina LINKEDIN dell’azienda:

https://www.linkedin.com/company/velo3d/

Visita il sito web dell’azienda: https://velo3d.com/